Joist Flooring in a Frame House

Our range of wooden flooring solutions, including double joist systems, is designed to meet the diverse needs of lightweight frame houses. These solutions offer enhanced structural integrity and improved insulation, ensuring your flooring is both aesthetically pleasing and resilient. Whether you’re looking for durability, style, or both, our wooden flooring options are perfect for creating a cozy and comfortable living environment in your frame house.

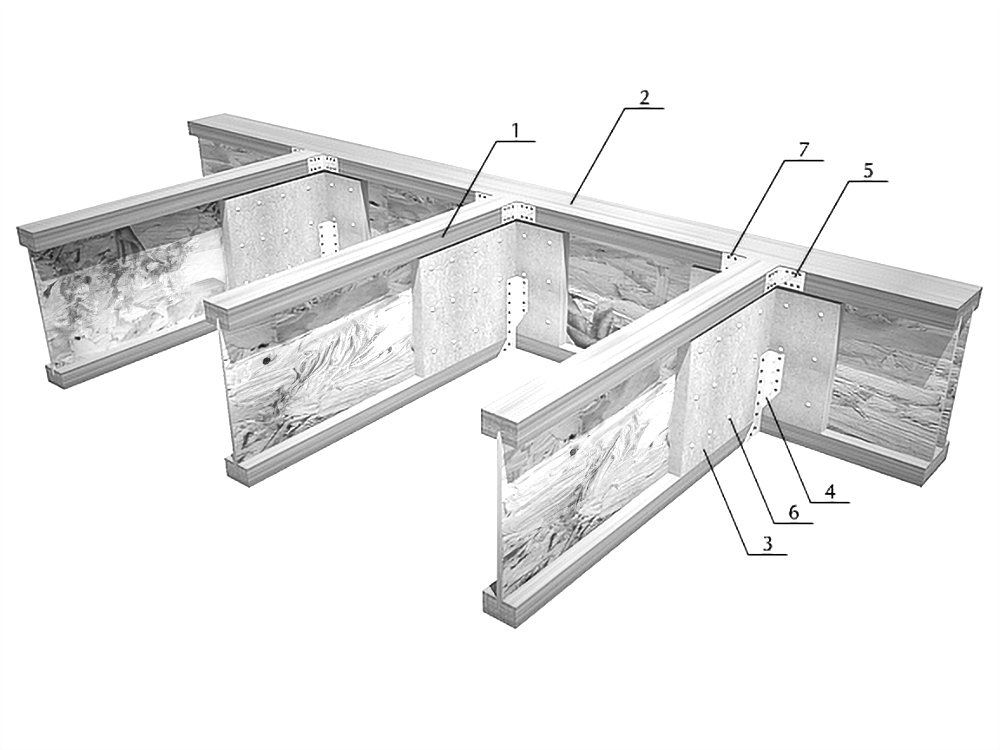

Node 1: Butt joint to a twin beam, supported by brackets

This node is commonly used in staircase designs and in instances where main joists need to be suspended from brackets attached to a twin beam rigel.

Materials and Components:

- Wooden I-beams (main joists)

- Twin I-beams (rigel)

- Insert block (plywood/OSB/board)

- Bracket for beam support

- Structural angle bracket

- Galvanized nails/screws

- Installation screw 4.0×30

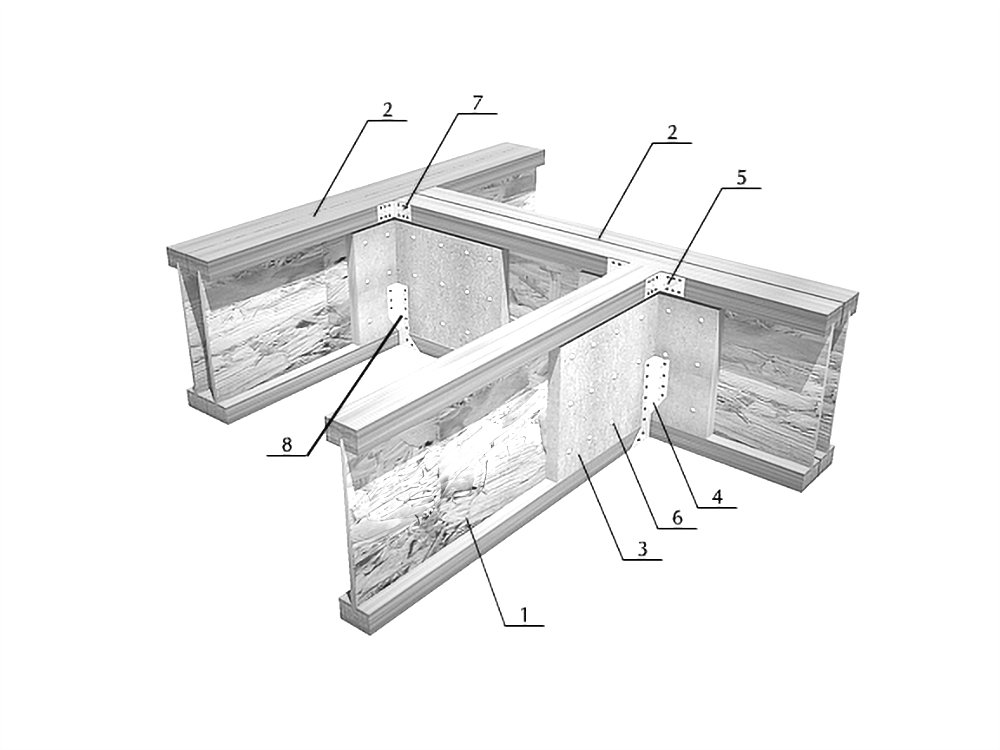

Materials and Components:

- Wooden I-beams (main joists)

- Twin I-beams (rigel)

- Insert block (plywood/OSB/board)

- Bracket for beam support

- Structural angle bracket

- Galvanized nails/screws

- Installation screw 4.0×30

- Bracket for beam support specifically for twin beams

Node 2: End-to-end connection of a twin beam to another twin beam, supported by brackets

This configuration is utilized in designs for wide-span joists with complex structures, such as when a staircase or an atrium is centrally positioned within the span.

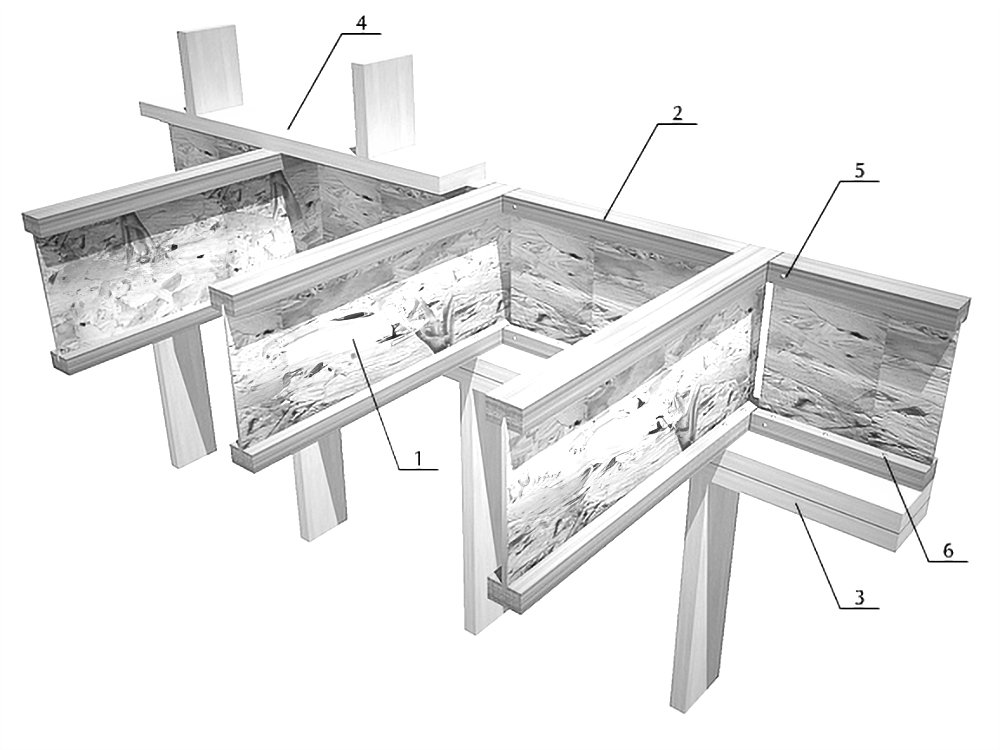

Node 3: Support for external walls on flooring, with joists perpendicular to the external walls

This setup is used when the main joists of the floor are perpendicular to the external walls. Blocking beams are installed at the ends between the main joists to secure the I-beams in a vertical position and to distribute the load from the wall. External walls can be mounted directly on the beams or on pre-installed subfloor boards.

Materials and Components:

- Wooden I-beams (main joists)

- Block beams

- External wall of the first floor

- External wall of the second floor

- Galvanized nails/screws angled at 30 degrees horizontally

- Galvanized nails/screws angled at 30 degrees vertically

Materials and Components:

- Rough covering (OSB-3 panels, plywood, boards)

- Vapor barrier

- Insulation

- Wooden I-beams (joists)

- Vapor barrier or waterproofing

- Lathing on the lower flange of the I-beam (strips of OSB-3, plywood, or timber)

This setup effectively combines multiple layers to enhance both sound and thermal insulation, ensuring a robust and energy-efficient floor structure.

Node 4: "Layer Cake" Flooring Variant

This method involves the use of mineral wool or basalt fiber insulation as soundproofing and thermal insulation materials.

| Height | Profile 50 | Profile 70 | Profile 90 | Profile 95 (Double) | Profile 95 (Double, Insulated) |

|---|---|---|---|---|---|

| 15cm | 6€/m + VAT | 7€/m + VAT | 8€/m + VAT | 11€/m + VAT | 11,5€/m + VAT |

| 20cm | 6,5€/m + VAT | 7,5€/m + VAT | 8,5€/m + VAT | 12,5€/m + VAT | 13€/m + VAT |

| 25cm | 7€/m + VAT | 8€/m + VAT | 9€/m + VAT | 14€/m + VAT | 14,5€/m + VAT |

| 30cm | 7,5€/m + VAT | 8,5€/m + VAT | 9,5€/m + VAT | 15,5€/m + VAT | 16€/m + VAT |

| 35cm | 8€/m + VAT | 9€/m + VAT | 10€/m + VAT | 17€/m + VAT | 17,5€/m + VAT |

| 40cm | 8,5€/m + VAT | 9,5€/m + VAT | 10,5€/m + VAT | 18,5€/m + VAT | 19€/m + VAT |

| 45cm | 9€/m + VAT | 10€/m + VAT | 11€/m + VAT | 20€/m + VAT | 20,5€/m + VAT |

| 50cm | 9,5€/m + VAT | 10,5€/m + VAT | 11,5€/m + VAT | 21,5€/m + VAT | 22€/m + VAT |

Need experts advice? Let us help you.

+370 682 81 811

Contact Us