Joist Flooring in a Brick House

Our wooden joist flooring is the perfect addition to brick houses, combining elegance with robustness. The double joist system enhances the floor’s strength, making it capable of supporting heavier loads while maintaining its stylish appearance. This solution is ideal for those looking to upgrade their brick homes with a flooring system that is both durable and visually appealing, ensuring a timeless and sturdy foundation.

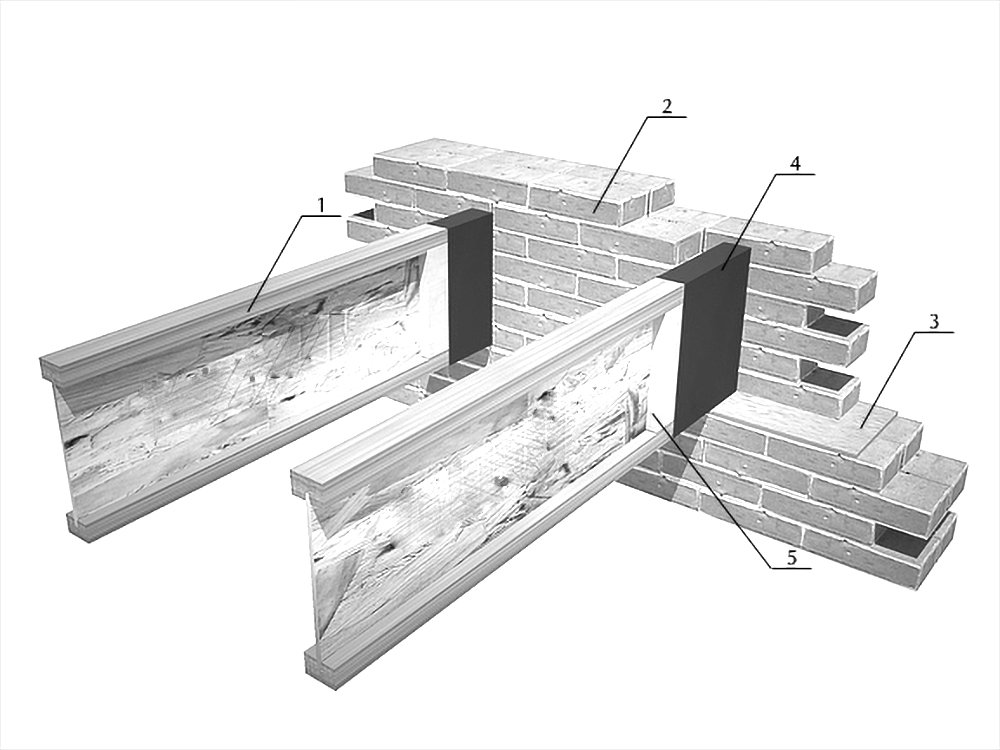

Node 1: Support of I-beam Joists on Brick Masonry

The most optimal solution for supporting floor joists on an external load-bearing brick wall. Inserts made from OSB, plywood, or board can be used to strengthen the I-beam at the support point. The insert should have a 5 mm gap from the top flange of the I-beam, with a minimum width of 30 cm. The beam should rest 15 cm on the wall. All wooden structures must be protected from contact with cement using waterproofing.

Materials and Components:

- Wooden I-beams (main joists)

- Brick masonry

- Cement screed over masonry

- Waterproofing (hydro barrier or mastic)

- Insert made from OSB-3/plywood/board, 30 cm wide

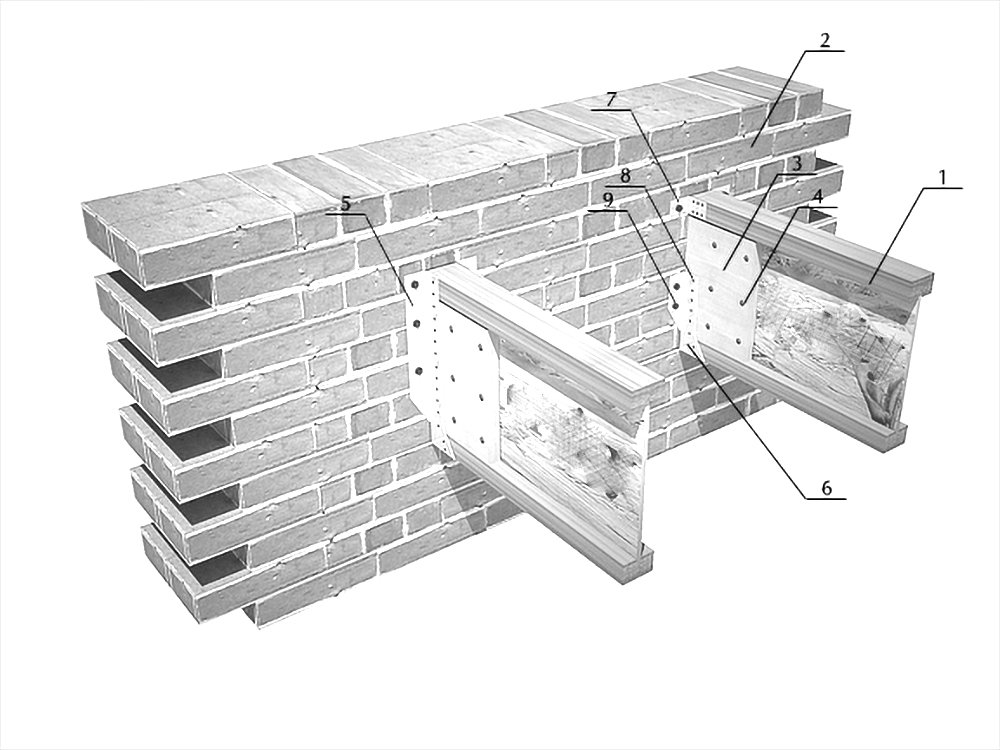

Materials and Components:

- Wooden I-beams (main joists)

- Brick masonry

- Insert made from OSB-3/plywood/board, 30 cm wide

- Galvanized nails/screws

- Full-height Simpson bracket

- Beam support

- Structural corner bracket

- Installation screw 4.0×30

- Anchors

Node 2: Attachment of I-beam Joists to Brick Walls Using Brackets

This node is used when it is not possible to rest the beams directly on the masonry from above. The joists are suspended on brackets (beam supports) anchored into the brick. The lower flange of the beam is “shod” into a bracket, while the upper flange is secured with a structural corner bracket. A more advanced, yet more expensive method of attachment involves using full-height Simpson brackets for the beam, which need to be ordered in advance. At the support points, the I-beams are filled to their full cross-section with inserts made of plywood/OSB or board; a 5 mm gap should be maintained between the insert and the upper flange of the I-beam

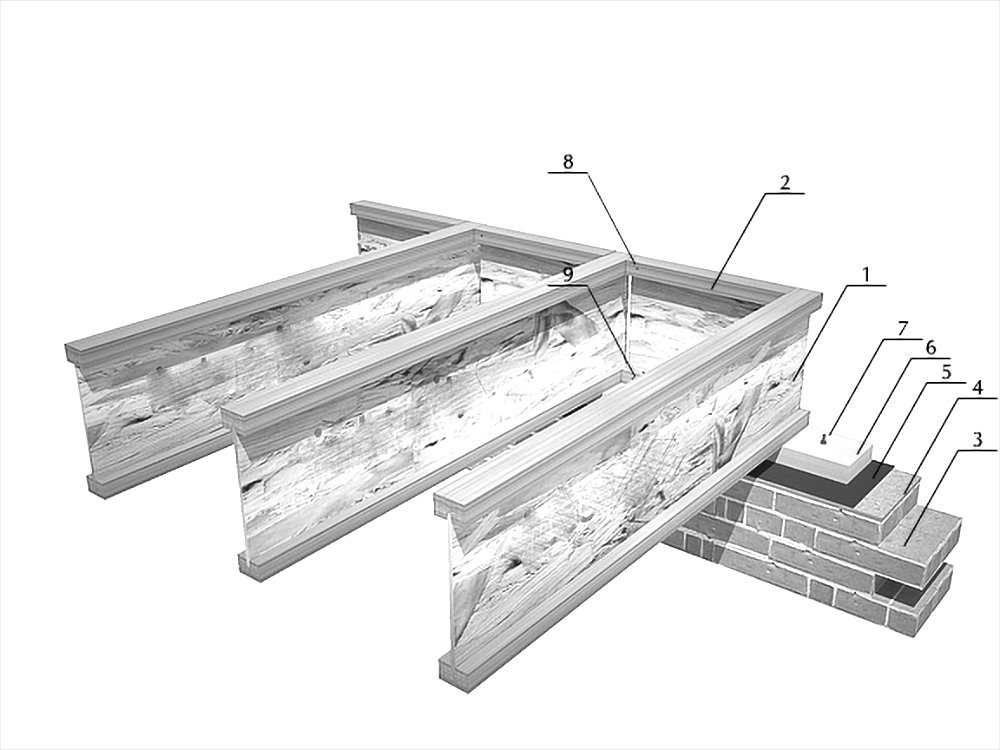

Node 3: Support of I-beam Joists on a Tie Beam Along the Final Course of Masonry

This node is used when no brick masonry is planned above the flooring, such as with a framed second story or where the roof truss system is directly supported on the I-beams. In this case, the masonry is completed with a reinforced screed, to which a tie beam (board or beam) is attached using anchors through waterproofing. The I-beams are then screwed into the tie beam. Refer to the section “Flooring in a Frame House.”

Materials and Components:

- Wooden I-beams (main joists)

- Block beams

- Brick masonry

- Cement-sand screed (reinforced)

- Waterproofing

- Tie beam

- Anchors

- Galvanized nails/screws angled at 30 degrees horizontally

- Galvanized nails/screws angled at 30 degrees vertically

Materials and Components:

- Rough covering (OSB-3 panels, plywood, boards)

- Vapor barrier

- Insulation

- Wooden I-beams (joists)

- Vapor barrier or waterproofing

- Lathing on the lower flange of the I-beam (strips of OSB-3, plywood, or timber)

This setup effectively combines multiple layers to enhance both sound and thermal insulation, ensuring a robust and energy-efficient floor structure.

Node 4: "Layer Cake" Flooring Variant

This method involves the use of mineral wool or basalt fiber insulation as soundproofing and thermal insulation materials.

| Height | Profile 50 | Profile 70 | Profile 90 | Profile 95 (Double) | Profile 95 (Double, Insulated) |

|---|---|---|---|---|---|

| 15cm | 6€/m + VAT | 7€/m + VAT | 8€/m + VAT | 11€/m + VAT | 11,5€/m + VAT |

| 20cm | 6,5€/m + VAT | 7,5€/m + VAT | 8,5€/m + VAT | 12,5€/m + VAT | 13€/m + VAT |

| 25cm | 7€/m + VAT | 8€/m + VAT | 9€/m + VAT | 14€/m + VAT | 14,5€/m + VAT |

| 30cm | 7,5€/m + VAT | 8,5€/m + VAT | 9,5€/m + VAT | 15,5€/m + VAT | 16€/m + VAT |

| 35cm | 8€/m + VAT | 9€/m + VAT | 10€/m + VAT | 17€/m + VAT | 17,5€/m + VAT |

| 40cm | 8,5€/m + VAT | 9,5€/m + VAT | 10,5€/m + VAT | 18,5€/m + VAT | 19€/m + VAT |

| 45cm | 9€/m + VAT | 10€/m + VAT | 11€/m + VAT | 20€/m + VAT | 20,5€/m + VAT |

| 50cm | 9,5€/m + VAT | 10,5€/m + VAT | 11,5€/m + VAT | 21,5€/m + VAT | 22€/m + VAT |

Need experts advice? Let us help you.

+370 682 81 811

Contact Us